Maintenance-free separation technology

INOWA System H - the intelligent separator system.

With the INOWA separator, the separation process works purely hydro-dynamically withou using coalescence material.

1

- Purely hydro-dynamic action

- No filter materials such as

- PU foam plastic, rippled or bevelled plates

- ...maintenance-free separation technology

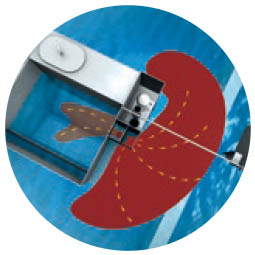

- Inflow closure is located directly at the inlet to the sludge trap. This prevents a build-up in the whole separator system so that if water continues to enter no light liquid can enter the soil

- No need for shaft to protrude above ground level

- If approved by the authorities, a warning system is not required. Country-specific regulations apply.

- Factory installed cable leadthrough

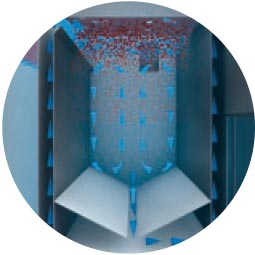

Oil-free surface in the INOWA separator thanks to automatic oil withdrawal into a separate oil tank.

3

- Oil-free surface until the maximum oil storage volume is reached

- Purely flow-related function, without density sensitive floats, skimmers, etc.

- Light liquid and water are screened in the separator

- Disposal using separate oil tank saves costs and guarantees uptime - even while disposing of oil

- Flood-proof design of the oil storage tank

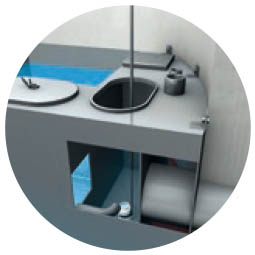

- Oil suction port including C-coupling and oil level measurement

- The float triggers when the maximum level of the light liquid is reached and also reacts if there is a build-up due to hydraulic overload

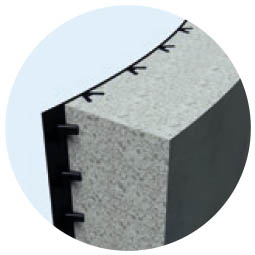

- PEHD inliner for maximum mechanical and chemical resistance

- DIN 1999100 requires the inside surfaces to be coated or lined. INOWA is the only manufacturer that since 2000 has integrated the PEHD inside lining into the DIBT approval

- Also available in double-walled version to monitor leakages

- No separate sampling chamber required (refer to country-specific requirements)

- Less space required

- Optional - sampling directly integrated in the separator according to DIN 1999-100 in agreement with the authorities

INOWA System H >