Verbund Hydro Power AG, Austria

Hydroelectric power plants, Danube, Drau

REQUIREMENTS:

SOLUTION:

- Discharge of waste water leaking from the turbines into an inspection passage at a depth of 25 metres, including drainage for the whole building

- In the event of a seal rupture, this inspection passage can be flooded

- If there are high levels of oil leakage due to a defective seal, oil may enter the water

- During operation, mussels accumulate, and during floods there are also increased levels of silt, which clogs the conventional separators installed

- The client therefore attached great importance to good accessibility, easy cleaning and the longest possible cleaning intervals!

- With the conventional existing separators, it was difficult to clean the various filters and involved a great deal of work

SOLUTION:

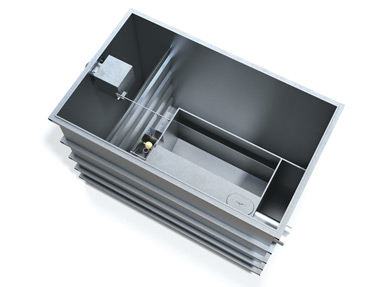

- Because there are no filters in the high-performance separator, the maintenance required and the simplicity of maintenance have been reduced to a minimum

- Due to confined space conditions, the high-performance separator was developed with a folding mechanism that facilitates accessibility for cleaning (free of mud and mussel growth)

- Since there is an acute risk of flooding in the event of a malfunction, the high-performance separator was equipped with an automatic oil tank closure

Ing. Klaus Wölbinger (now retired) -

Verbund Austrian Hydro Power:

„The process technology must be precisely adapted to our specific on-site conditions. The impressive features of this separator system made INOWA stand out.“